Customer Introduction

The case shared this time is the comprehensive treatment of waste gas from a waste electronic product dismantling company.

This client is mainly engaged in the dismantling and utilization of waste electrical and electronic products. It is one of the "first batch of waste electrical and electronic product treatment fund subsidy enterprises" announced by the Ministry of Finance, the Ministry of Environmental Protection (now the Ministry of Ecology and Environment), the National Development and Reform Commission, and the Ministry of Industry and Information Technology in 2012.

The customer's dismantling volume is about 170,380 t/a; the waste gas treated in this project includes:

① Waste gas (particulate matter, mercury vapor) G2-1 generated during the dismantling of CRT and LCD;

② Dust (phosphor, lead-containing) G2-2 generated by the separation, cutting and cleaning of CRT screen cones;

③ Dust G2-3 (particulate matter) generated during the dismantling of air conditioners and washing machines;

④ Refrigerant volatilized during the extraction of air conditioner refrigerant (particulate matter, Freon, cyclopentane, etc.) G2-4;

⑤ Waste gas (particulate matter, Freon, cyclopentane, etc.) G2-5 generated during the dismantling of air conditioners and small household appliances integrated lines;

⑥ Waste gas (particulate matter, Freon, cyclopentane, etc.) G2-6 generated by the crushing and dismantling of small household appliances and fluorine-containing refrigerators;

⑦ Waste gas (particulate matter, Freon, cyclopentane, etc.) G2-7 generated by the crushing and dismantling of R600a refrigerators;

⑧ Dust generated by the crushing of household appliances and plastics G2-8 (particles);

⑨Dust G2-9 (particles) generated by the crushing of refrigerator plastics (drawers, partitions);

Solution

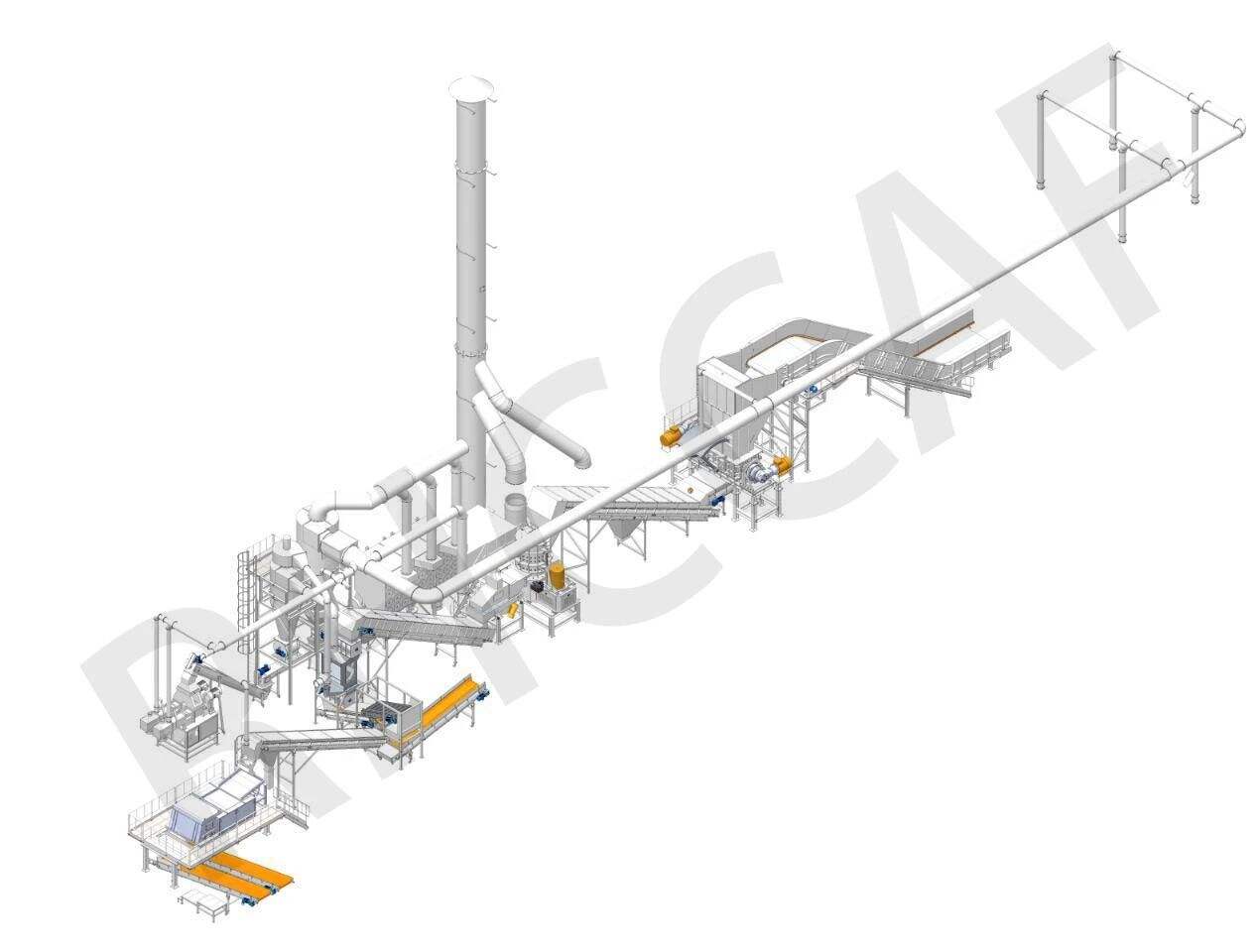

With years of accumulated experience and technical accumulation in various industries, the Renhe team tailored a comprehensive waste gas treatment plan for the company after full communication with the customer during the design phase of the project:

Each disassembly station on the disassembly line is equipped with a closed compartment, which is equipped with a gas collection hood system, and the disassembly station is slightly negative pressure (collection efficiency 95%). The exhaust gas is passed through the down-flow Filter Cartridge (heavy metal and particulate purification efficiency > 99%) + secondary high-efficiency filter (heavy metal and particulate purification efficiency > 99.9%) + sulfur-loaded activated carbon adsorption (mercury vapor and NMHC adsorption efficiency > 85%) through the fan; after filtration, it is discharged through the high-altitude exhaust pipe.

Governance Effectiveness

After comprehensive treatment, the on-site waste gas is collected through closed equipment and closed spaces to reduce the unorganized fugitive emission of waste gas; after the waste gas is collected, it is purified by corresponding filtering equipment to ensure that the waste gas can be discharged in compliance with the standard and meet the local total emission indicators of waste gas pollutants.

According to the completion environmental protection acceptance report, the monitoring results of the unorganized waste gas emissions at the factory boundary after the actual application of the project are as follows: the maximum value of total suspended particulate matter is 0.474 mg/m³, the maximum value of non-methane total hydrocarbons is 1.27 mg/m³, the maximum value of fluoride is <0.5ug/m, and the maximum value of lead and its compounds is <1.25* 10-6 mg/m³.

In summary, the project results obtained are that the particulate dust collection rate is ≥95%, and the purification efficiency after collection is ≥99%; the heavy metal dust collection rate is ≥99%, the filtration efficiency after collection is ≥99.9%, the non-methane total hydrocarbons are ≥95%, and the purification efficiency after collection is ≥85%. The total amount of pollutant emissions has been reduced on the basis of nearly 3 times the expansion of waste electrical and electronic products.

After treatment, the waste gas has been discharged up to standard, and the concentration of unorganized waste gas pollutants at the enterprise boundary has reached the corresponding boundary standard. The implementation of the project will not lead to changes in the regional environmental quality level, will not have an impact on the regional environmental quality bottom line, and can promote the healthy development of the local economy. It truly achieves the unity of social benefits, economic benefits and environmental benefits.