- Overview

- Related Products

HOW IT WORK

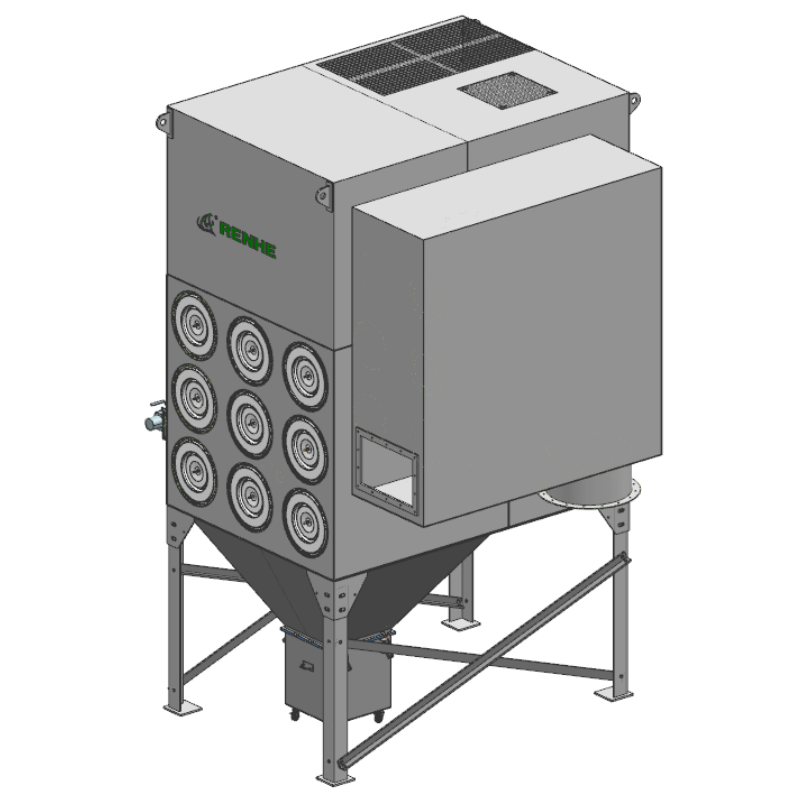

The dirty air through the arm goes into the filter room, firstly hits the flow distribution plates and changes the direction, then the air flow goes upward which protects the filter element and a cycle is over, also the big particles is filtered. The fine dust goes through the PTFE Membrane Filter Cartridge and if filtered. The clean air after de-nosing process is released outside, the whole filter process finishes. The filtered dust falls into the dust container by the pulse dust-cleaning. The filter elements are horizontally loaded, the filter media is high efficiency membrane. The filter media ensures the dust cleaning efficiency and prolongs these device life. This wholly new-designed dust collector can meet the indoor emissions standards stipulated by the state.

FEATURES

Multi-welding station.

Imported components

Large air flow, low noise and good suction efficiency.

High filter efficiency, emission concentration lower than the nationa0

standard.

PLC microcomputer automatic dust-cleaning.

Easy to handle, move.

Flexible hose or stiff hose for your choice

TECHNICAL SPECIFICATION

Name |

RH/HY-150 |

RH/HY-200 |

RH/HY-300 |

RH/HY-400 |

Filter area |

10/20 |

10/20 |

20/40 |

40/80 |

Size of filter cartridge |

Φ350*660 |

|||

Air flow |

1500 |

2000 |

3500 |

4000 |

Power |

2.2KW |

3.0KW |

4.0KW |

5.5KW |

Qty of arm |

1 |

1/2 |

1/2 |

With dust hood |

Size(W*D*H) |

740*1147*1286 |

740*1147*1286 (without HEPA) 740*1147*1636 (with HEPA) |

740*1147*1726 |

1000*1085*1330 (without fan) |

APPLICATION

Welding smoke

Cutting smoke

Griding dust