Renhe offers a comprehensive range of industrial dust collectors designed to enhance workplace air quality and ensure compliance with environmental regulations. Our Industrial dust collector systems are engineered to efficiently capture and filter airborne particulate matter, minimizing health risks for workers. Whether you operate in the manufacturing, construction, or food processing sectors, our dust collectors are tailored to meet your specific needs, ensuring optimal performance and reliability. Explore our advanced solutions today and transform your facility into a cleaner, safer environment.

Both effectiveness and compliance are vital elements of every industrial process and Renhe's industrial dust collectors enable industries to achieve both. Amid issues like air pollution and workplace hazards as result of industries, there is a need for most industries to buy better dust collectors in order to make sure they are compliant but still productive.

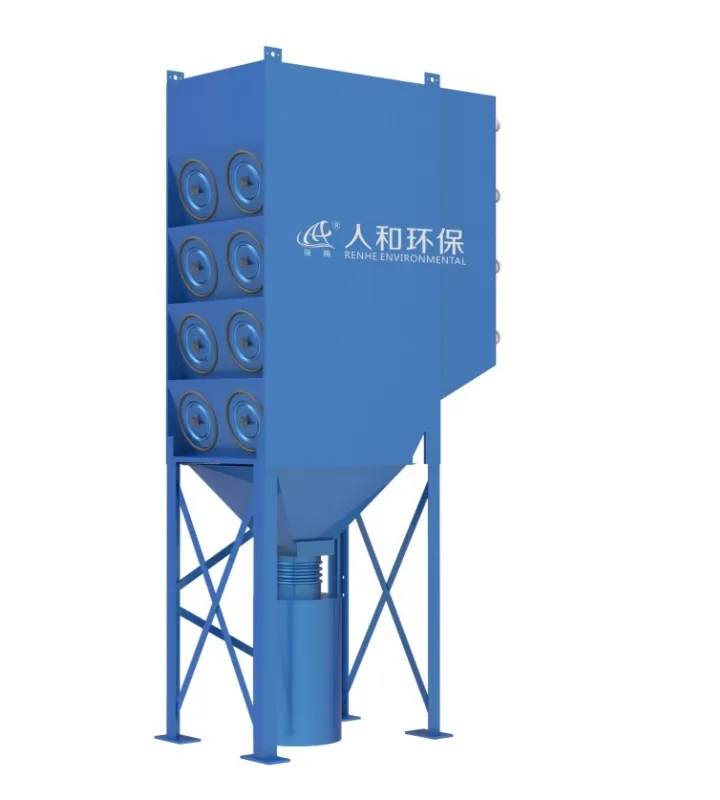

Also, Renhe's industrial dust collectors are manufactured to collect dust right from the point of its generation to eliminate the risk of dust inhalation in a workplace. Including a selection of advanced filtration techniques such as HEPA filtration and pneumatic multi-filtration systems our dust collectors guarantee that the air is reintroduced only after it has efficiently gone through the dust removal process. Air quality is improved this way, and as a result, people occupy less air pollution from industrial activities.

In the contemporary industrial setting, the importance of air quality is associated with the protection of workers and the optimum performance of the tasks. Renhe provides advanced industrial dust collector systems that are created to eradicate process generated particles and enhance the quality of air in your space. Our dust collectors are made with innovative systems that are able to filter a large variety of dust such as fine dusts and particles, to create a safer working environment.

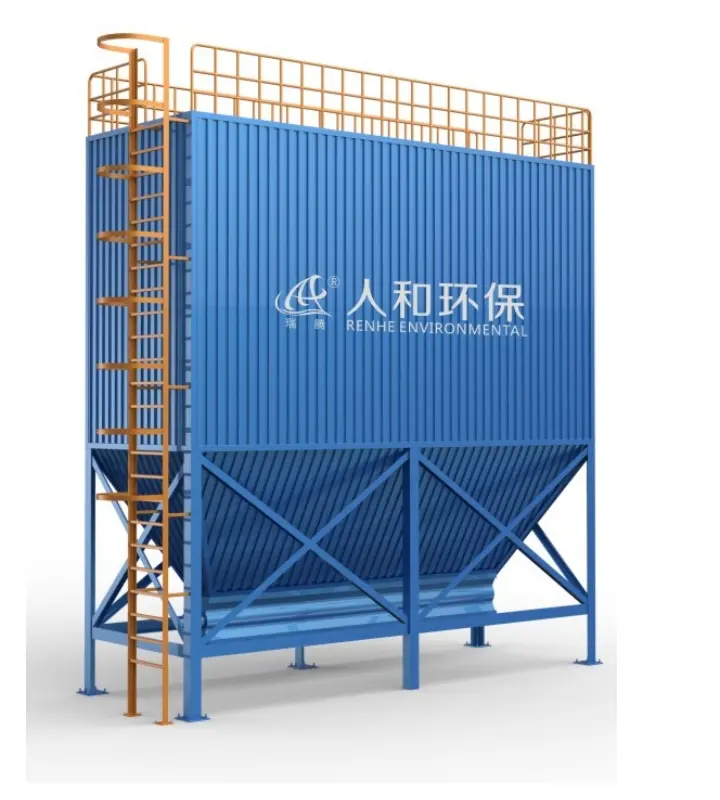

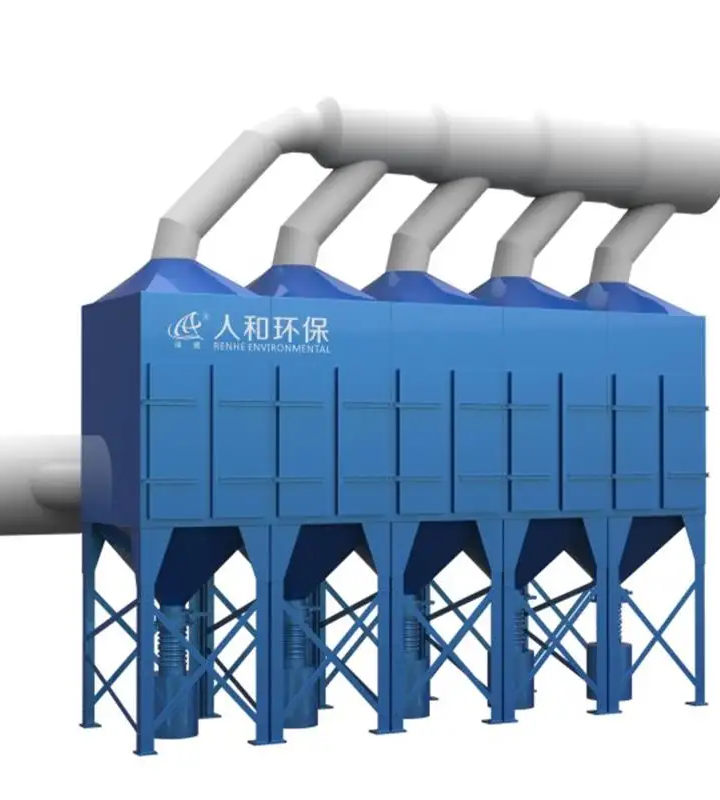

Due to the various configurations of the industrial dust collectors, these machines serve different industries. Be it dusty production lines in manufacturing, wood and metal workshops, or food processing, Renhe dusty control systems fit the relevant dust sources. The working principles of our products are such that they withstand large dusty operations.

Another beneficial factor of Renhe’s industrial dust collectors is their low energy consumption. High performance systems of dust control have been achieved without excessive consumption of power by means of using cutting edge venting systems. In addition, our units come with serviceable processes that support the durability of the units.

An industrial dust collector must be chosen depending on several criteria such as the kind of dust produced, airflow needs and the arrangement of the premises. There is a team of professionals at Renhe who will help the operations managers to choose what type of dust collector is most appropriate for their operations. Whatever your needs, we have all to include drum dust collector, cyclone dust collector or bag house dust collector.

In the industrial industry restrictions positioned with dust removal are extremely important in the overall work performance and safety of the workers in the organization. Renhe provides all such industrial productive dust collectors that such the dust problems in every field from the production of goods to the production of food. The systems have been designed to ensure the safe and efficient collection of dust littered in the work environment.

Renhe’s industrial vacuum cleaners also called dust collectors have advanced types of filters that help increase the collection of both large and small particles of dust. Dusts produced from woodwork, metal dusts, and chemical powders are among other materials our dust collectors have the capacity to work on efficiently. This makes them most suitable in plants where dust is generated from many sources.

One of the most distinctive features about our dust collectors for industrial usage is the strong design of the industrial dust collectors. Renhe designs systems that operate efficiently and reliably under the tough conditions of everyday industrial use. These units are formed in a chipboard style and can be used as building blocks so that when requirements change in the future, they can be expanded or modified. This capacity is important in the modern world of manufacturing industries where most processes and laws are being changed all the time.

In every industrial setting, worker safety is paramount, and that is why Renhe's industrial dust collectors must be incorporated into the industrial processes for any safety level. They all have a number of advantages including reducing the risk of respiratory problems for the employees since they are able to ventilate the harmful dust and other pollutants that are generated at the points of generation. Particularly in some industries such as construction, mining, and manufacturing, where dust is inevitable, purchasing appropriate dust collection systems is very essential since it helps to comply with occupational health and safety requirements.

Renhe's industrial dust collectors are fitted with efficient filtration systems to capture the ultrafine dust particles present within the air. Cyclone dust collectors and wet scrubbers are also very effective and can be used in collection of various materials such as wood, metal and hazardous dust. Furthermore, you will be able to improve the working conditions of your employees by using our dust collectors as part of your operations which in turn will increase their efficiency and morale.

Another advantage that Renhe's dust collectors have is the reduction of air pollution and the corrosion of your machines. Too much dust within an operating machine can subject that machine to wear and tear hence repairs become a must and can lead to nonstop working hours. Our dust collection systems will aid in the reduction of this since we create a cleaner working environment bolstering the efficiency and even the deferral of the wearing out of your systems.

Jiangsu Renhe consists of Jiangsu Renhe Environmental Equipment Production Base (Jiangyin) and Jiangsu Renhe Energy-saving Equipment Technology Base (Zhangjiagang). Our company takes improving the environment and creating a cleaner living space as its business purpose, takes low-carbon emission reduction, energy saving and consumption reduction as its own responsibility, and provides intelligent integrated comprehensive services for enterprises.

The products produced are: air Filter Cartridge, gas turbine air filter, Pleated Filter Media, industrial dust, industrial dust filter Our company has maintained a rapid growth momentum since its establishment. Our main products have been recognized as high-tech products in Jiangsu Province , famous trademarks in Wuxi City, and CE certification. The company has won the honors of Jiangsu High-tech Enterprise, "Specialized and Special new" Enterprise, Jiangyin Key Enterprise, Three-star Enterprise, Advanced Enterprise in Cultivating Technological Talents and Brand Building , and so on.

Offering durable filters designed for optimal performance.

Comprehensive selection for various industrial applications.

Utilizing state-of-the-art processes for superior quality.

Skilled professionals ensure top-notch product quality.

Industrial dust collectors come in several types, including baghouse dust collectors, cartridge dust collectors, cyclone separators, and wet scrubbers. Each is designed to handle specific types of dust and airflow requirements. For example, baghouse dust collectors are ideal for high-volume dust applications in industries like cement or metalworking, while cartridge dust collectors are suitable for fine particles in pharmaceutical and food processing.

An industrial dust collector works by capturing airborne particles and filtering them out before they can circulate in the workplace. This significantly reduces the amount of hazardous dust in the air, ensuring a cleaner environment. Renhe’s dust collectors can help lower the risk of respiratory issues among workers and improve overall air quality, making the workspace safer and more compliant with regulatory standards.

Regular maintenance of dust collectors is crucial to ensure optimal performance. This includes cleaning or replacing filters, inspecting hoses and seals, and checking the functionality of the dust collection system. Routine inspections help to identify any potential blockages or issues early on, ensuring that the dust collector continues to operate efficiently and reduces the risk of downtime.

The primary difference lies in the filtering mechanism. Cartridge dust collectors use pleated filters, which are more efficient for capturing fine dust particles. Baghouse dust collectors, on the other hand, use fabric bags that are better suited for handling large volumes of dust and larger particles. Industries requiring high dust load capacity, such as foundries and cement plants, often prefer baghouse systems, while cartridge systems are favored in applications like food and pharmaceutical production.

Selecting the right industrial dust collector depends on factors such as dust type, airflow requirements, facility size, and regulatory compliance. Understanding the nature of the dust (whether fine, abrasive, or sticky) and the volume produced will guide the choice of system. Renhe offers various options that can be tailored to meet specific industrial needs, ensuring that dust collection aligns with operational demands and industry standards.